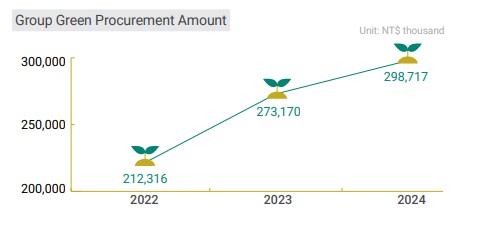

In addition to creating a green corporate culture and an environmentally friendly workplace, a company shall leverage its influence from the procurement perspective to reduce the negative environmental impact of its own operations— encouraging and practicing green consumption, helping increase the market share of green products, and in collaboration with suppliers to factualize sustainability initiatives.

The Company not only focuses on the growth of the Group's business, but also attaches importance to the control of procurement risks and the implementation of responsible procurement. We have invited suppliers to join sustainable action to create a resilient and sustainable future by promoting sustainable supply chain management.

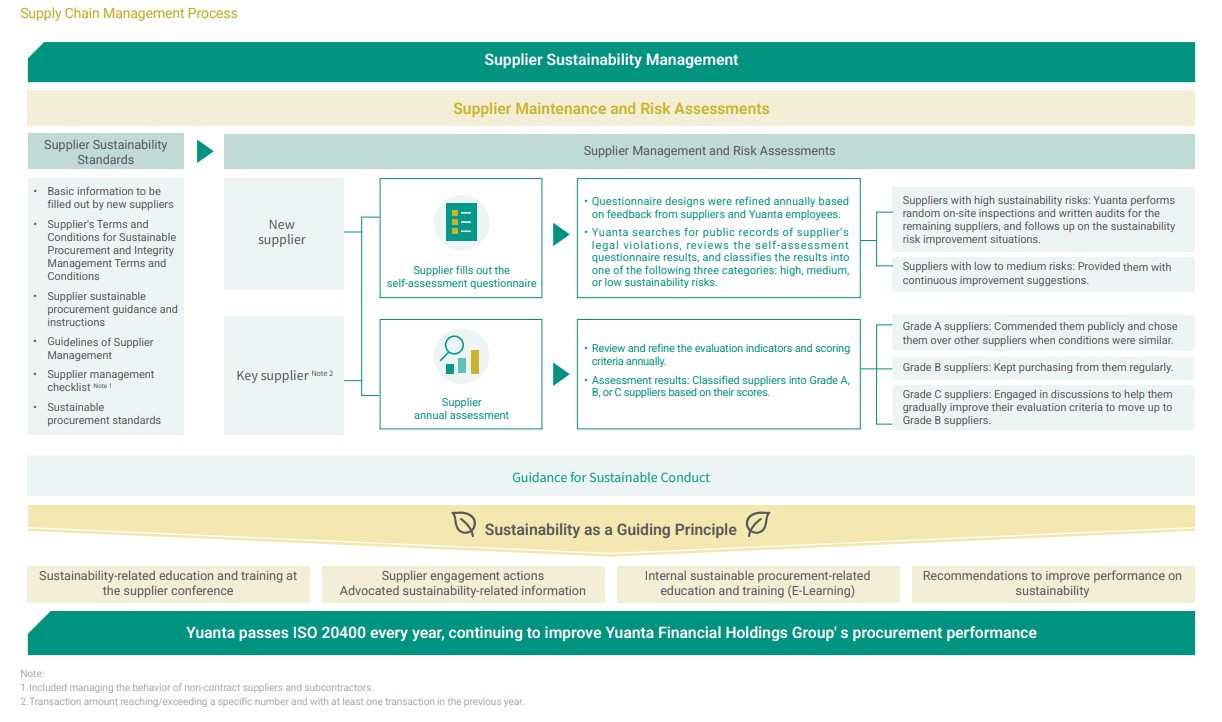

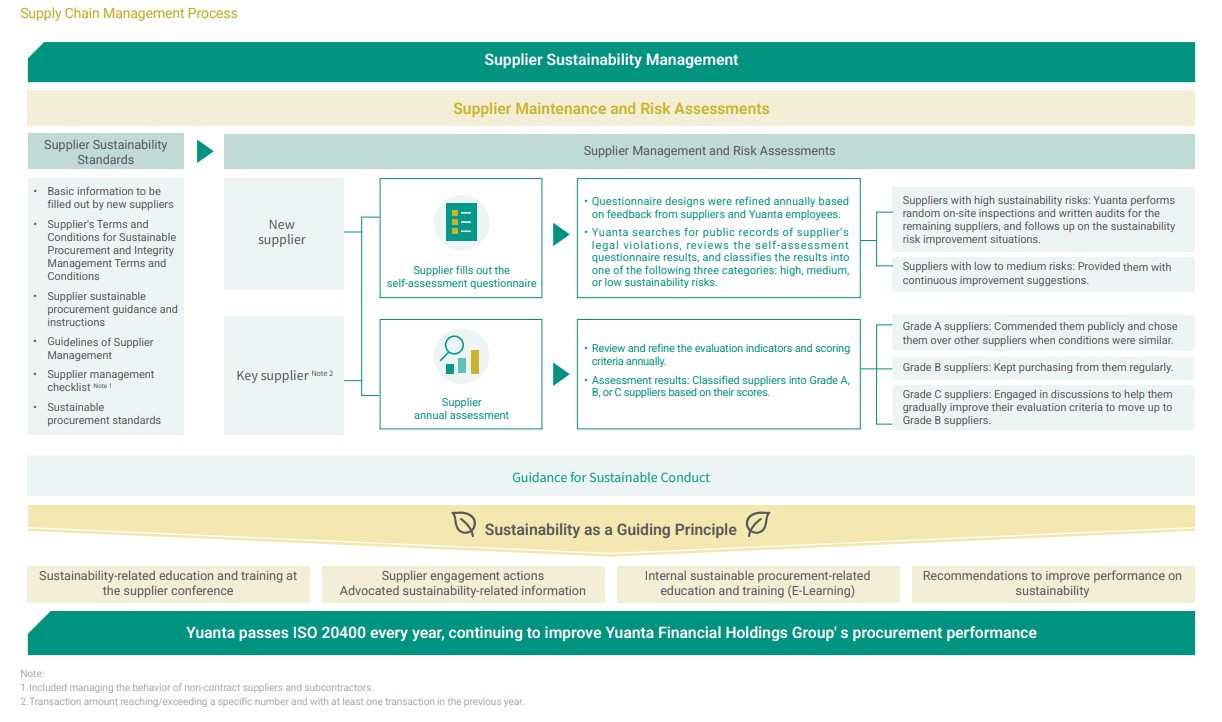

This year, 100% of suppliers with contractual relationships met our sustainability standards. In addition, we continue to screen and evaluate new and existing suppliers according to the "Key Points for Procurement of Goods" and ESG three dimensions that was established internally. At the same time, we consider the conditions of bribery-related Judicial Yuan record, the size, professionalism and experience of the suppliers, and acquisition of international standards, etc., and conduct terrorism financing checks on major suppliers of procurement amount of NT$25 million or more. Only those who pass the checks become qualified suppliers of the Company. For suppliers without formal contracts, the Group Supplier Management

In addition to creating a green corporate culture and an environmentally friendly workplace, a company shall leverage its influence from the procurement perspective to reduce the negative environmental impact of its own operations— encouraging and practicing green consumption, helping increase the market share of green products, and in collaboration with suppliers to factualize sustainability initiatives.

The Company not only focuses on the growth of the Group's business, but also attaches importance to the control of procurement risks and the implementation of responsible procurement. We have invited suppliers to join sustainable action to create a resilient and sustainable future by promoting sustainable supply chain management.

This year, 100% of suppliers with contractual relationships met our sustainability standards. In addition, we continue to screen and evaluate new and existing suppliers according to the "Key Points for Procurement of Goods" and ESG three dimensions that was established internally. At the same time, we consider the conditions of bribery-related Judicial Yuan record, the size, professionalism and experience of the suppliers, and acquisition of international standards, etc., and conduct terrorism financing checks on major suppliers of procurement amount of NT$25 million or more. Only those who pass the checks become qualified suppliers of the Company. For suppliers without formal contracts, the Group also communicates expectations through awareness efforts, including the Integrity Management Guidelines and Supplier Sustainable Procurement Guidance.

Sustainable Procurement Declaration

Supplier Selection Process of the Group

Suppliers who sign contracts with us, in accordance with the company’s “Procedures for Integrity Management and Guidelines for Conduct”(hereinafter referred to as “Conduct Guidelines”), are required to comply with the terms and conditions of the “Integrity Management Guidelines” and “Conduct Guidelines”. In addition, to facilitate the evaluation of procurement contracts with suppliers, the Company conducts supplier management checks when suppliers provide their quotation.

Sustainable Supply Chain

Supplier Feedback and Complaints

To safeguard stakeholders' rights to seek remedies and to continuously improve sustainable procurement practices, the Group has established a comprehensive supplier grievance mechanism, which is publicly available on its official website. Suppliers and relevant stakeholders can submit complaints— either with their names or anonymously—through the supplier feedback and grievance channel. This mechanism is open to employees, suppliers, and other stakeholders. As of 2024, no complaints have been received through the supplier grievance mechanism. The Group is committed to maintaining strict confidentiality for any future cases, protecting the privacy of involved parties while ensuring fairness and impartiality throughout the investigation process.

- Types of cases received by the Feedback and Complaints Channels: cases related to integrity management, labor rights, environmental protection, procurement processes, and procurement transactions.

- Feedback and Complaints Channels:

Stakeholder communication channels are available (link below)

https://www.yuanta.com/EN/ESG/Stakeholder-Engagement/Contacts

- The Company will encourage stakeholders to use these channels to provide feedback or concerns by engagement.

Supplier Sustainable Procurement Guidance

In order to establish a better "sustainable procurement process", the Group's subsidiaries continued to introduce and obtained certification for the ISO 20400 Sustainable Procurement Guidance from 2021 onwards. Through systematic management of the sustainable procurement process, we have implemented the concept of sustainability in the procurement process of all subsidiaries. In terms of management system, the Group has required subsidiaries to incorporate the "Supplier's Terms and Conditions for Sustainable Procurement "and "Integrity Management Terms and Conditions" into the procurement contract with major suppliers. The terms and conditions specify that suppliers are to fulfill and comply with various laws and regulations of labor conditions, occupational safety and health, environmental protection, and labor human rights, etc. The contract also contains a clause which stipulates the contract may be terminated or canceled if suppliers violate the relevant laws and regulations.

Supplier Management

(1)Supplier Annual Self-Assessment

The company enhances its sustainable supplier management by continuously optimizing the supplier self-assessment mechanism and questionnaires each year. In 2024, these self-assessment questionnaires were revised based on the results of an internal sustainable procurement risk analysis. In addition to evaluating the five major aspects of human rights, labor practices, environment, fair operations, and consumer issues, the questionnaire now includes more advanced topics such as biodiversity, human rights risk assessments, and greenhouse gas inventories. The results from the self-assessments are used to analyze the current risk levels of key suppliers, categorizing them into major deficiencies, general deficiencies, and legal violations, and also to understand their sustainability practices. This analysis helps classify suppliers into three risk levels: high, medium, and low. By doing so, we can effectively monitor and address specific deficiencies, ensuring that any risks remain under control.

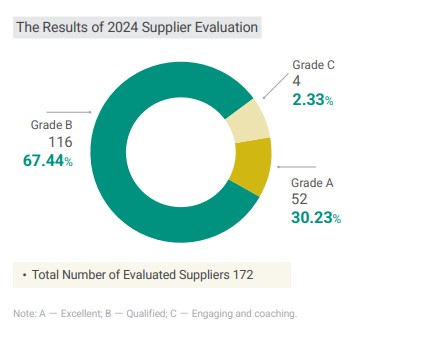

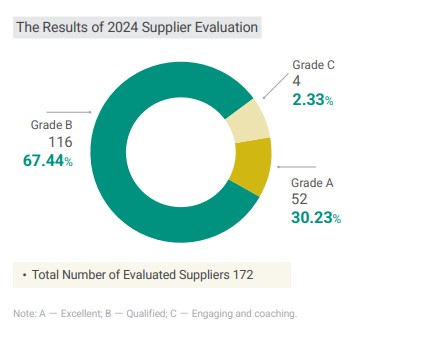

In order to enhance suppliers' sustainability awareness and self-awareness, the Company advocates the supplier self-assessment mechanism through three supplier conferences held each year, individual communications, training, and promotions. In addition, to increase the response rate and the suppliers' awareness of sustainability, we will communicate and follow-up on the individual supplier that do not turn in the self-assessment form. The Company posted a self-assessment questionnaire response rate of 100% this year, achieving this year's target. The questionnaire was sent to key suppliers across the Group with annual procurement amounts over NT$2 million, and also included newly added suppliers in 2024 and those rated as "Grade C" in the previous year—a total of 172 suppliers.

Supplier Human Rights Due Diligence Investigation Table

(2) Supplier Evaluation

The Company hopes to encourage and guide our suppliers to continuously enhance product and service quality through implementing the self-assessment mechanism, as well as developing sustainable actions. In accordance with the "Guidelines of Supplier Management", the Procurement Department conducts an annual evaluation of major suppliers, covering: (1) The top 150 suppliers in annual transaction amounts with the Group; (2) The top 5 suppliers in annual transaction amounts with Yuanta subsidiaries in the previous year; and (3) New suppliers of Yuanta subsidiaries evaluated in the previous year. The evaluation is based on the seven core themes of the ISO 20400 Sustainable Procurement Guidance and other relevant international standards. Based on the assessment results, major suppliers are classified into three grade levels: A, B and C (Note). Grade A suppliers are commended publicly at supplier conferences and selected over their competitors if they offer similar conditions during price comparison, negotiation, or supplier selection processes. Grade C suppliers will receive enhanced training and will be re-evaluated the next year for tracking purposes. The Company may refuse to do business with suppliers rated as Grade C for 3 consecutive years. Furthermore, if a supplier is found to violate sustainable development policies resulting in considerable negative environmental and social impacts, the Group will refuse to deal with the supplier.

Note: A-Excellent; B-Qualified; C-Engaging and coaching.

Supplier Risk Control Procedures

(3) Supplier Education and Training

We are committed to promoting sustainable corporate development. In addition to our own efforts, we also ask our supplier partners to fulfill corporate social responsibility and join the ranks of sustainable actions. In addition to promoting its sustainability values through direct communication with suppliers via letters, the Company further advocates ESG principles and the spirit of sustainable development through supplier conferences and educational training, inviting suppliers' participation in the journey toward sustainability.

In 2024, we held three supplier conferences. A total of 90 major suppliers participated. Through this event, we share the concepts and practices of supply chain management and sustainable procurement and explain how to make the most of corporate social influence and actively embrace a new future of sustainability. We give recognition to Grade A suppliers with excellent sustainable performance; each year, the theme is changed to facilitate suppliers to get on board with the new trends in sustainability and the invitations are adjusted according to different themes and major suppliers. This year's supplier conference covered both environmental and social themes, which gather suppliers and partners to jointly implement carbon reduction actions, seeking solutions to climate change, and continue to deepen sustainable influence.

元大金控

元大金控